At 219, we combine mechanical, electrical, and software disciplines to help our clients make extraordinary things happen. Designing test fixtures is a perfect example of this. We’ve built test fixtures for a wide variety of products and devices in the medical, industrial, and consumer spaces. This article is meant to give those who need a test fixture for their embedded device some helpful hints and things to consider.

219’s Philosophy on PCB Test Fixtures

Build Them Early and Reliably

Test fixtures for embedded electronic devices are central to developing integrated products. They can be used for production and quality control but, if you can build them early enough, they can also assist with development and become a part of your engineering infrastructure. Test fixtures can range dramatically in sophistication from simple pass/fail power tests to the multi-parameter measurement of an analog signal.

It is often required for a test fixture to be more reliable or better characterized than your device under test (DUT). This means that fixtures might be more complicated than the device you’re testing. Modularity is desirable because your fixture may be a work in progress. If your test requirements change or your device under test changes, having the ability to adjust your test fixture is most advantageous.

Electro-Mechanical Interface

Secure Your PCBAs

A successful fixture starts with a good mechanical connection securing your device under test (DUT). The optimal strategy will depend on your form factor and the type of tests to be run. Here are some of the ways we secure different categories of PCBAs.

Low Density Connections

- Weight It Down: a heavy object can be surprisingly effective; think paper weight. This could work with a large area device, if testing a multitude of units in parallel, or if you just do not want a pivot or press mechanism.

- Exposed circuit board pads can function as a test contact. For soft goods or other niche situations, you would want your finish to be ‘hard gold’ for reliability.

Intermediate Density Connections

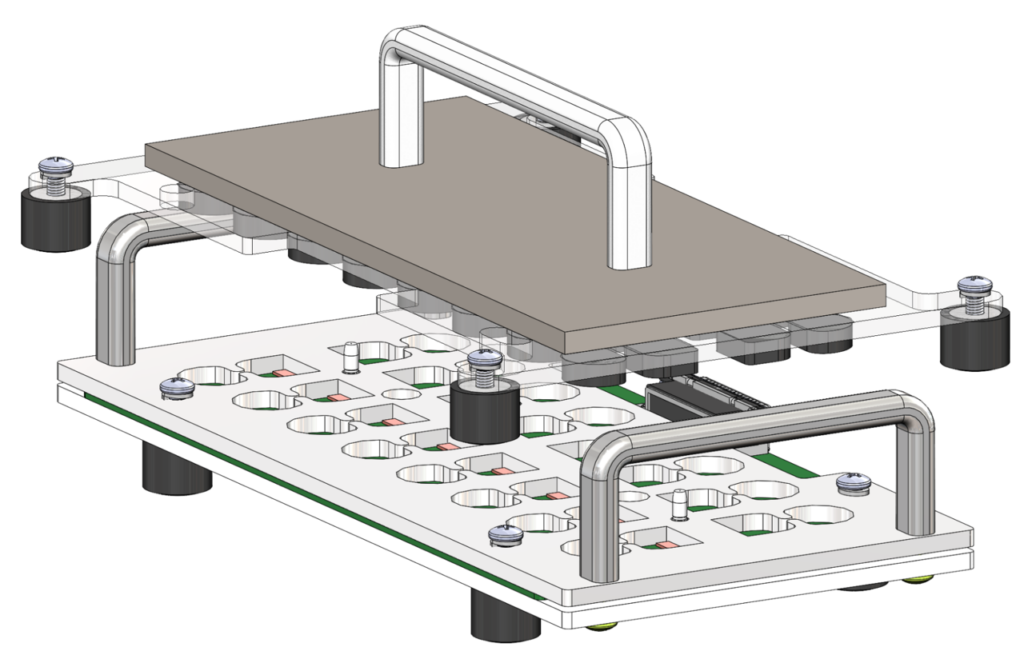

- Hinged lids or toggle clamp or press; think waffle maker (1).

- It is always preferred to have the electrical access points be made from a single plane, but if needed, you can interface with a DUT from the top and bottom and/or (gulp) side, with connectors on linear slides or spring pins.

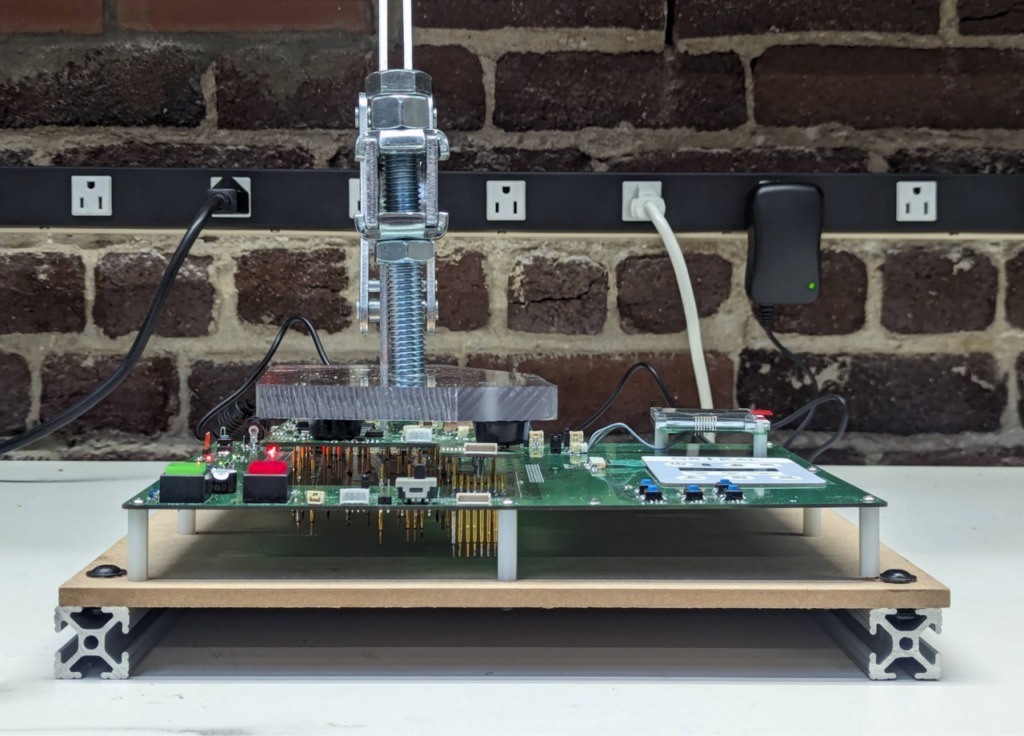

- Spring pins (2) – typically spring pins want to compress about ⅔ of their nominal travel. Mechanical spring force is important to evaluate to reduce the deflection of the device under test, especially if your PCBA is thin or has a lot of test points that are unevenly distributed.

- If the test fixture involves mating a connector, whether performed with a mechanism or with manual operator dexterity, then consider your cycle count. You may need to incorporate more robust connectors.

High Density Connections

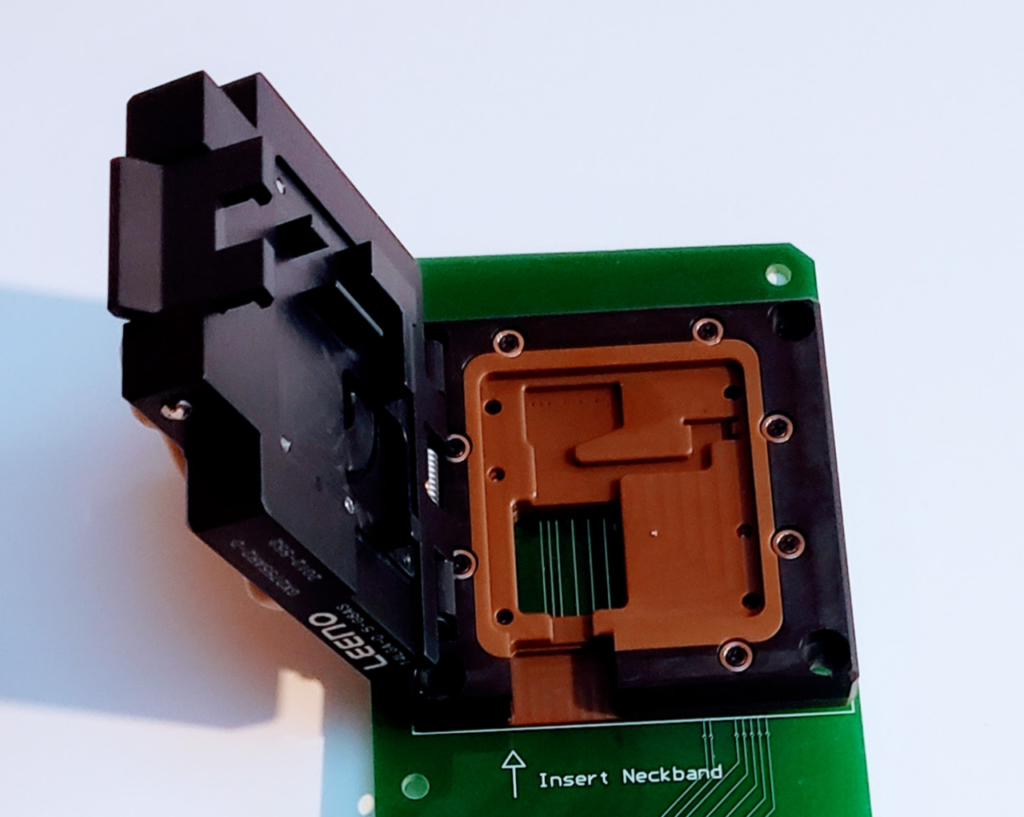

- Sockets or clam shells are better for smaller devices and flex boards; think Jello Mold. Sockets are commonly used for integrated circuits but similar designs can also be used for PCBA assemblies.

- These fixtures might be fully customized to one’s design and provide the required access of the DUT. It could be precision machined or 3d printed. Sometimes these units must be mounted on a carrier test board, as pictured below. This fixture can allow greater mechanical precision and allow for higher density electrical connections (3).

Materials to Use

- Magnetics: make nice latches

- 3D printed parts: fast and adaptable

- Particle board/wood: great for early prototypes

- Acrylic: easy to laser cut and transparent, ideal for seeing what’s happening inside

- Delrin: very machinable

- T-slotted aluminum rail (80/20): provides extra stiffness for demanding tests

Electrical Systems

Use Bench Equipment

It is often desirable to use existing bench equipment with good interfaces to accelerate your development of a test fixture. This equipment can be expensive, but it reduces the development time. Tool examples:

- Mini PC: a mini computer can help log data and remote monitoring

- General purpose input and output controller: for sequencing to simulate a certain operating state (4)

- Custom PCBA: You may want a custom PCBA with some simple circuit logic with a few inputs (buttons) or indicators (LEDs or buzzers)

- Non-contact interfaces: bluetooth dongle, NFC coil, etc.

- Four quadrant power supply or battery simulator: these can emulate a battery to ensure performance at a low state of charge or other critical conditions (5)

- Oscilloscope: if you have an analog waveform that needs to be verified, an oscilloscope with Windows API can be used to acquire and process (6)

- Automated cable tester: test opens, test shorts, and perform higher performance measurements like impedance and / or voltage withstand (7)

- Serial communication tool: useful for interfacing and debugging hardware (8)

We’re Here For You

Your Fixture Fixer

Test fixtures should be highly accurate, mechanically reliable, and if your product is not very mature also adjustable. Building such a fixture is a significant engineering challenge, but the fixture can also accelerate product development and improve manufacturing efficiency and quality. We have designed test fixtures of varying degrees of sophistication and sometimes for products we did not design. Using an external engineering team for test fixtures can allow you to focus on the primary product, lest you get caught in the infinite loop of designing the device-to-test the device.

If you would like help with a test fixture, feel free to reach out to us at GetStarted@219design.com!

Glossary

Alignment Pin – a coarse mechanical guide to align the device under test

Device Under Test (DUT)- any device that you are hoping to inspect with the help of your fixture. Typically a rigid circuit board

Functional Test – generally speaking a low sophistication simple test, perhaps just pass / fail

PCBAs – printed circuit board assemblies

Performance Test – tests that result in the output of a value(s) which may be logged

Pressure Plate – the surface that provides mechanical compression to secure the DUT

Probe Plate – the surface that serves up the probes to the DUT. It may include electrical circuitry

Reference Units – these are units that ensure the fixture is operating normally. These could be designed to intentionally fail and or pass the test

Useful Links

- Premade mechanical jigs: Cortek

- Spring Pins: Ingun

- Clam Shell fixture: LEENO

- GPIO Controller: MCDAQ from Digilent

- Battery Simulator: 2281S Battery Simulator from Keithly

- USB Oscilloscope: Picoscope

- Cable Test Instrument: Cirris

- Serial communication: Total Phase from Aardvark