Purcell is bringing disruptive innovation to the grocery aisle. 219 Design and Purcell have teamed up to design a sustainable, modern IoT solution for food merchandising. The S1 introduces a new way to merchandise that moves the packaging to the purchase phase – eliminating those half empty bags and boxes we are all only too familiar with.

Making A Real Difference

On average Americans throw away ~728,000 tons of trash (enough to fill 63,000 garbage trucks). That’s more than 250 million tons per year and most of this trash will end up in a landfill near you. Why is that a problem? There are many reasons, but the three main dangers are toxins, contaminated liquid, and greenhouse gases. What about recycling? The short answer is that for the most part, it’s just not happening at the scale required.

Purcell saw an opportunity to make a real difference. Food packaging makes up about 75% of that trash. The founders were determined to solve the problem of excessive packaging by bringing bulk food to the mass market. The Purcell solution makes sustainability a business advantage. In addition to the significant environmental benefits, a modern bulk food solution also reduces costs, increases profit margins, improves hygiene, allows people to buy only what they need, and more.

In 2018, the Ocean Conservancy found that, of 23.3 million pounds of trash on beaches in more than 120 nations, plastic packaging from food was the most commonly found item.

Smart Bulk Food Dispenser for Purcell

Sustainability as a Business Advantage

Client Vision

To Reduce Food-Related Waste

“Working with 219 gave Purcell access to a depth of knowledge and experience we could not find anywhere else. Their ability to see weak points and more efficient design paths helped us avoid countless mistakes.”David Conway, Co-Founder

Purcell

Modernizing Food Merchandising

The Purcell S1 isn’t just a bulk food dispenser, it’s a brand new way to merchandise food. As a result, Purcell needed a development partner with experience across software, firmware, mechanical, and electronic engineering. They also needed a development firm with a breadth of expertise spanning IOT connectivity, sensors, displays, microcontroller, load cells, mechanism design, mobile app development, and more.

Building The First Prototype

219 Design was hired to develop the first fully functional S1 prototype. Part of our process is to break large scale projects into smaller phases to address high-risk areas early on. This ensures that we are always making incremental progress while working toward the main goal.

Phase 1: De-risking and System Architecture

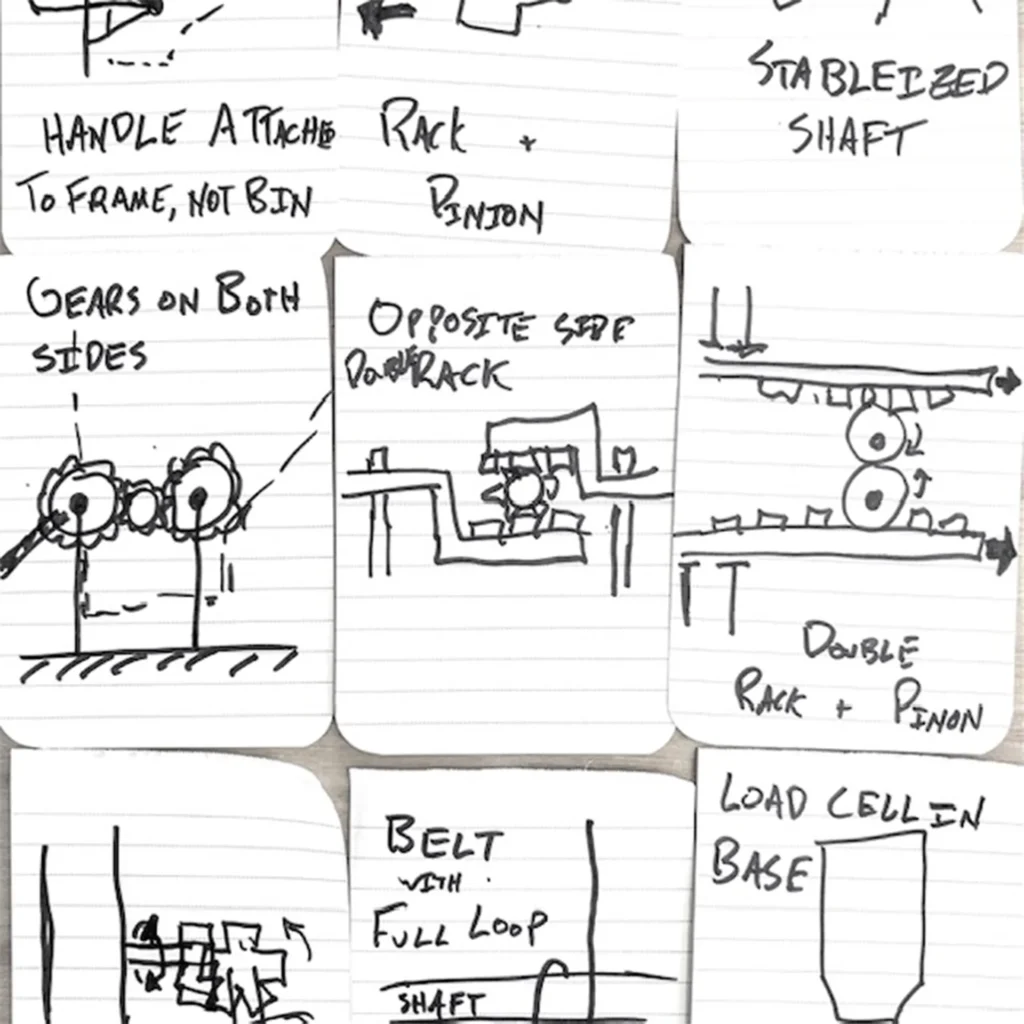

During this phase, we focused on developing the overall system architecture, as well as addressing several areas of known technical risk.

We were able to converge on a simple, low-cost solution to one of the primary technical challenges: by using pull-cables and isolated mounting points, we were able to fully decouple the forces on the dispensing handle from the load cell the bin was resting on.

Phase 2: Detailed Design

With Phase 1 complete, we then transitioned into the Detailed Design phase. This is where the core of our engineering development takes place and was focused on developing a fully-specified design for the pilot build. Rather than working in silos, our mechanical, software, and electronic teams came together and worked as a team to design a cohesive solution.

Phase 3: Final Prototype Integration and Build

Phase 3 was focused on integrating, debugging, and preparing the S1 prototype for pilot deployment.

The Solution

The result is a hygienic IoT-enabled dispenser for the merchandising of many free-flowing products using a proprietary, airtight, and standardized cartridge system. Both the retailer and shopper benefit from lower costs, immersive marketing experiences, portion control, and zero waste.

“We put a lot of effort into finding projects where we can not only add value, but that also make a difference in the world. Purcell’s S1 was a perfect combination of those two objectives. Our partnership and shared vision resulted in a fantastic solution.”Miguel Piedrahita, Co-Founder

219