We were thrilled when Carbon reached out to us for some help improving the functionality and robustness of the M2 3D Printer’s companion Smart Part Washer. This machine is a workhorse part washer that brings speed and quality to the process. While Carbon’s in-house team remained focused on core technology, we were able to apply our expertise in mechanism design to make this game changing machine even better.

Meet Carbon

Carbon is a 3D printing technology company that has reinvented the way polymer products are designed, engineered, and delivered. Their platform helps innovators deliver better products faster. “The Carbon DLS™ process combines versatile printers, advanced software, and best-in-class materials to deliver functional parts with end-use performance and aesthetics, helping engineers and designers to create products that outperform.”

Their Smart Part Washer is an instrumental part of that process. After using the high resolution M2 3D printer, the washer optimizes quality, speed, and cost by leveraging an automated process that saves 70% in labor per wash. As a result, prints are consistent, predictable, and thoroughly clean.

Smart Part Washer for Carbon

Enabling Creators Everywhere

Client Vision

To Enable Creators Everywhere to Make What the World Needs Right Now

“219 Design lightened the load for my team by taking a challenging problem out of our hands so we could focus on our core product. The design they produced for us has exceeded our requirements and I'm looking forward to working with the 219 team again in the future.”Ryan Powell, Engineering Manager

Carbon

The Challenge

Designing for Reliability

Carbon is always looking for ways to improve their products. When they wanted to develop their next generation part washer, they came to 219 Design. They needed extra bandwidth and design expertise to focus on specific improvements. We were able to hit the ground running due to our experience tackling mechanically complex issues with robust and well designed mechanisms.

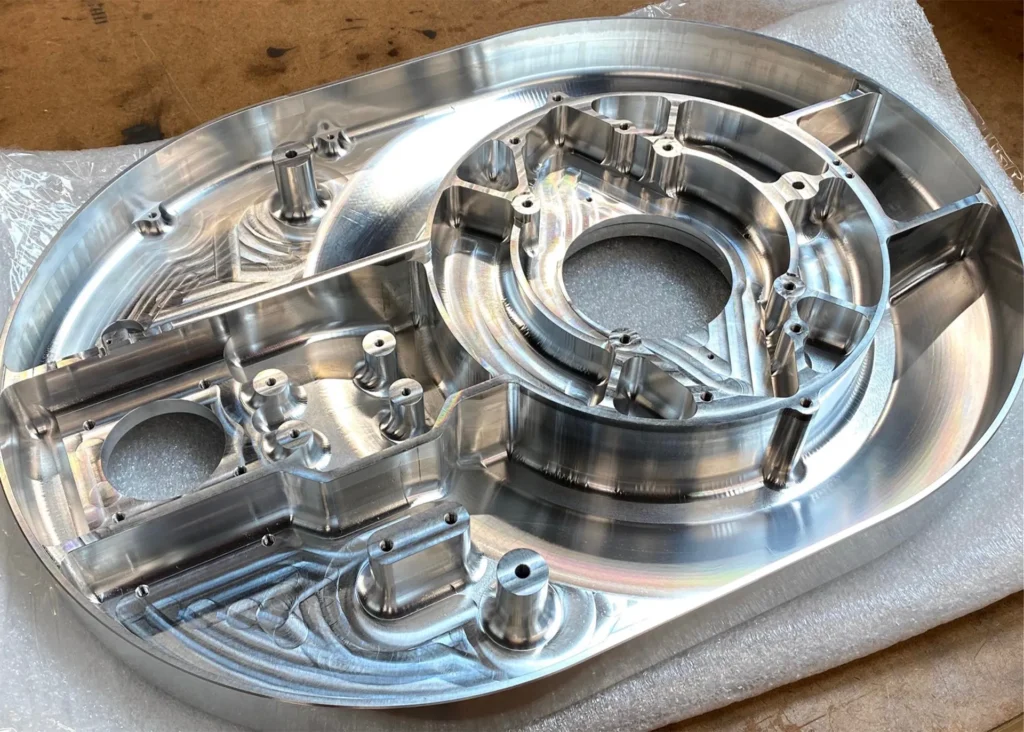

The Smart Part Washer is a device that cleans the residue off the 3D printed parts that are printed on the Carbon M2 printer. It submerges the printed parts in solvent and then spins and agitates the parts to dissolve the excess resin. This often results in aggressive spinning of an imbalanced load which produces high forces on the bearings in the system. The Smart Part Washer is spec’d to withstand these high loads over six years of continuous operation, which is the equivalent of over 200 million revolutions.

Our Approach

Design – Prototype – 3D Print – Iterate

219’s mechanical engineering team performed a full examination of the existing device. A fresh perspective and blank slate often leads to new insights. In this case, it inspired us to reimagine the approach to spinning a heavy, clamped, off-center load.

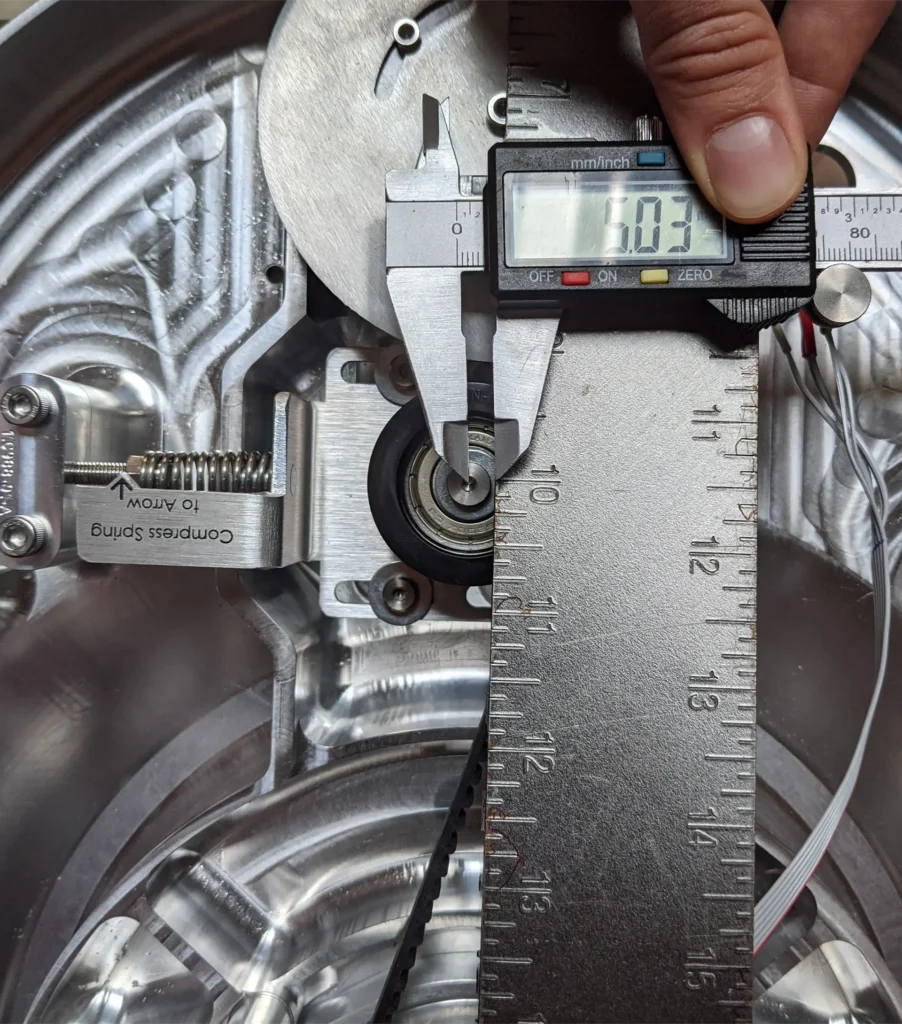

For each design problem, we brainstormed, prototyped ideas, and merged our thinking with Carbon’s past experience. Once our designs had progressed, the Carbon team generated the initial parts on their own in-house Carbon 3D printers. Where prototyping would be too expensive or slow, we turned to simulations to verify our intuitions. We performed finite element analysis on the shafts, fatigue calculations for the bearings, and moment calculations on essential bolts to ensure they could handle the most extreme cases. Through rapid iteration, we developed a design that could clamp, spin, and provide all the functionality we had hoped for.

The Results

Passing Tests With Flying Colors

The Carbon team ran the new Smart Part Washers through an accelerated life-cycle barrage to verify that the new design would withstand at least six years of hard use. All units successfully completed the test without issue.

Scaling from Prototyping to Mass Production

From a single functional prototype, we quickly scaled up and began manufacturing units ready for use in the field. We developed assembly guidelines, built fixtures, and made connections down the supply chain. Working beside the Carbon manufacturing team, first in 219 Design’s shop and then on Carbon’s assembly floor, we integrated the new generation Smart Part Washer back into Carbon’s flow of production.

“Working with respected technology leader, Carbon, to deliver the next generation solution to empower engineers to create great products was especially satisfying. We look forward to using this product ourselves!”Larry Miller, Founding Partner

219