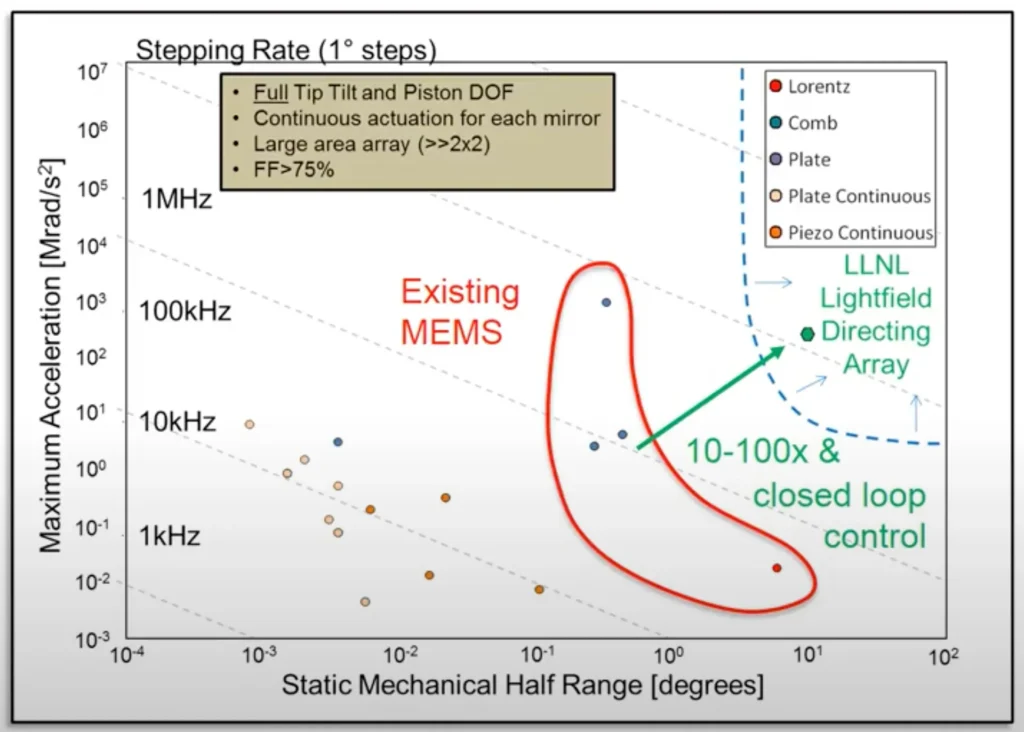

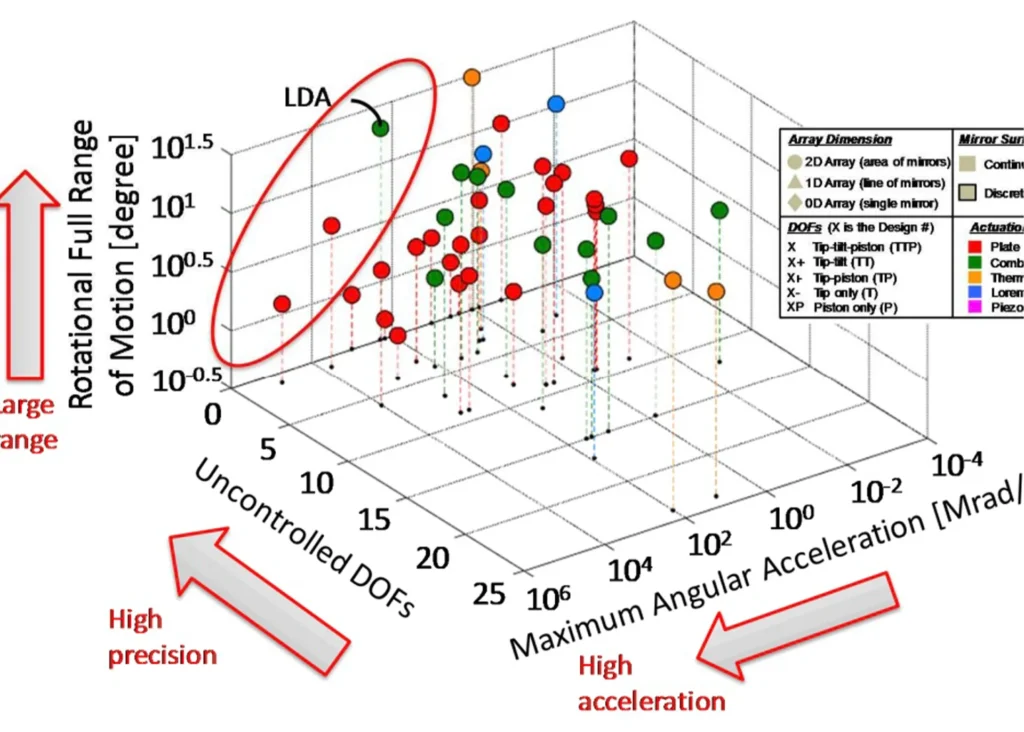

When Lawrence Livermore National Laboratory (LLNL) needed additional expertise to develop their Lightfield Directing Array (LDA), they came to 219 Design. The LDA, a high-speed large-angle micro-mirror array, is a solution to the limitations of existing micro electro mechanical systems (MEMS) beam steering. This technology could be a game changer for the autonomous vehicle industry, among others.

About Lawrence Livermore National Laboratory’s LDA

Lawrence Livermore National Laboratory is a federal applied science laboratory with a mission to develop and apply cutting-edge science, technology, and engineering in support of national security. Under development at LLNL by Dr. Robert Panas’ research group, Lightfield Directing Arrays are a new optical directing technology that promise a higher speed, range, and precision over those currently available.

Developing Lightfield Directing Arrays

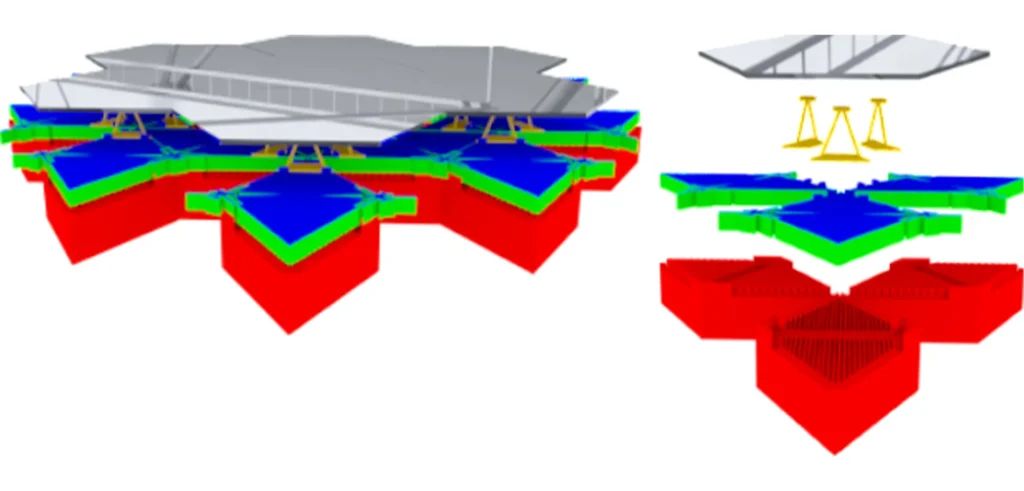

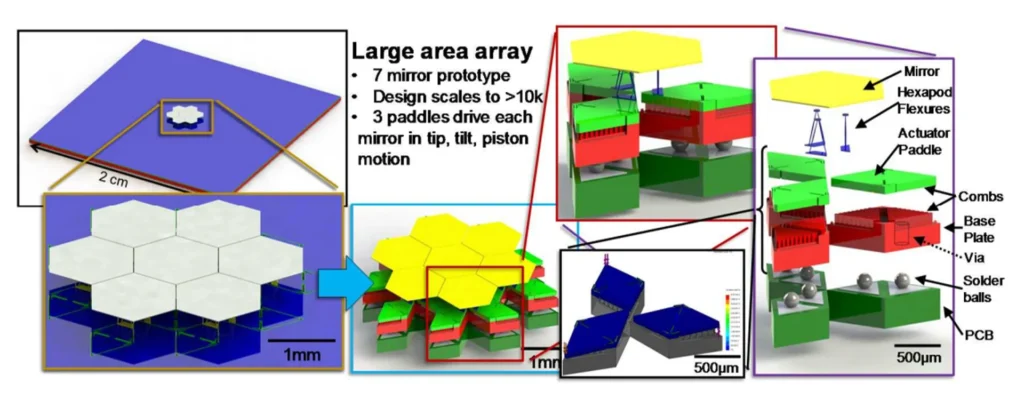

LLNL has leveraged insights across industries and new technology to reimagine the micromirror array. As a result, the devices promise stable images, repeatable scanning, faster refresh rates, adaptive resolution, and adjustable depth of focus. Because of its advanced flexure and actuator design with closed loop integrated sensing, it is able to deliver precision operation. Lightfield Directing Arrays improve existing technologies and open brand new possibilities. The advancements in precision and bandwidth are likely to enable advances in optical technologies such as LIDAR and augmented reality. The application of this technology could enable unique new optical technologies more quickly and inexpensively than ever before.

Lightfield Directing Array (LDA) for LLNL

Removing Limitations by Reimagining Technology

Client Vision

To Deliver Solutions for the Nation's Most Challenging Security Problems

“219 Design helped us break through the challenges in the difficult electronics back-end of our hardware. They were quick to dive into the electronic and mechanical challenge with our team and help us reach the solution we needed.”Robert Panas, Research Engineer

Lawrence Livermore National Laboratory

Our Role

219 Design was tasked with designing much of the analog electronics for the proof-of-concept drive system and feedback mechanisms, while keeping in mind the eventual plan to dramatically miniaturize the design.

Through the development of schematics, simulation, and circuit board layout, our work spanned multiple phases to implement position sensing and driving over several prototype generations. We also provided support through hands-on testing, review of testing methods/procedures, analysis of results, and input on the strategy and component selection to scale up to a greater number of mirrors.

Why Did LLNL Choose 219 Design?

As is often the case, we believe our tough questions earned their trust. We were honest about the challenges and potential roadblocks. We shared our ideas and our concerns. As a result, the team went into the project with eyes wide open and a mutual understanding of the task ahead.

That openness continued throughout the project. It became a critical part of our success when COVID shut down both offices and prevented us from working in the same space. We had to rely on each other to assemble, test, analyze, and debug. We worked as an extension of the LLNL team, increasing their bandwidth and providing specialized skills and problem solving.

In addition to COVID, there were various challenges related to designing this novel technology, including long lead-time parts and instrumentation/measurement challenges. Due to our past experience and cross industry expertise, we can often help further a project that may otherwise hit a roadblock.

Applications for the Automotive Industry

LDA’s show promise for many industries. The typical beam steering technology for LIDAR in self-driving cars has a number of weaknesses. In addition to being large and expensive, it also has a low refresh rate, low adaptability, and is weather dependent. LDA puts beam steering on a chip – providing a smaller, cheaper, faster, and more reliable option. This low cost, compact, reliable solution may help enable full autonomy for these vehicles as a game changing technology for autonomous vehicles. Additional real world applications for this technology include optical communications between satellites in space, laser surgery, and additive manufacturing.